Since all the sensors have been installed, I thought I had better install the extra wires required for the harness so that the sensors could be utilised. I laid the harness onto the engine and opened up the flexible conduit wrapping to add in the extra cores.

The wire was bought from SimtekUK, and are 1.00 sqmm in area.

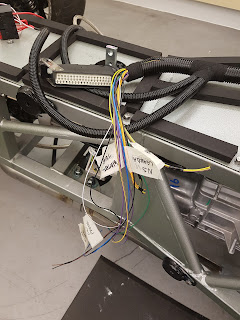

I used a mixture of black insulating tape and some fibre tape to close the conduit up again. I ran the following additional wires:

2x wires for the Oil Temperature Sensor

2x wires for the Oil Pressure Sensor

2x wires for the Coolant Temperature

2x wires for the Reverse Lockout Solenoid

4x wires for the Wideband Lambda Sensors (2x per side)

3x wires for the Oil Sump level Switch (May connect in the future)

I tried to work out how best to run the extra wires, and I decided to run them alongside the wires that go to the ECU connector. These will be fitted with connectors once the dashboard is fitted when I work out where everything needs to go.

I also dressed the engine harness using some stainless P-Clips and some short M10 Cap Head Set Screws.

I mounted the knock sensors to each side of the block. I used GM #12623730 sensors which are for the MK IV LS Engines. I realise now that I need the correct mating plug for them. I will change them when it they arrive. The mating plug part number is GM #13580877.

Once the starter was connected up, and the crank sensor plugged in, I fixed in the heatshield using one of the bellhousing bolts and an M10 Set Screw.

I crimped on the connectors for the following sensors:

Reverse Light Switch - Part Number Delphi 12015792

Vehicle Speed Sensor - Part Number Dorman 645-213

Reverse Lockout Solenoid - Part Number Delphi 12052646

3-Pin Sensors - Part Number GM #12551708 (CON-323 from SimtekUK)

Altogether quite neat I think. Just neat to finalise the harness onto the fuel rails: