There are a lot of theories regarding the steam vent system of the LS engines, and whether to leave the rear 2 blocked off or not. The theory is that air pockets form in the top of the head and can create hot spots. I think it depends on how level your engine is whether you should have them open or not....

I decided to play safe and buy a steam vent kit from the USA which links all 4 vents back to the header tank. I had to relocate the N/S lambda sensor connector bracket that I placed over one of the ports. I just made a new stainless steel bracket to mount it and bolted it to the block with a short M10 cap screw.

This also meant that I had to drill out the small plug that blocks off the port on the rear of both cylinder heads. I used a 3mm drill bit with lots of grease and a hoover to slowly drill out the plug. Once I was down a little bit, I tapped the hole out to put in a M4 bolt. This then allowed me to plug out the plug without causing too much mess!

I gave the water jacket a good hoover, to ensure no swarf had entered in.

I plugged the holes with paper towel temporarily to prevent any further entry of bits. I will provide an update once I have fitted the steam vent kit.

GD427 MK IV

One of my first drives out - 8th September 2025 (St Ninian's Isle - Shetland)

Showing posts with label Sensors. Show all posts

Showing posts with label Sensors. Show all posts

Thursday, 11 January 2018

Sunday, 12 March 2017

Engine Fuel System / Wiring - Complete!

I managed to find some more time in the garage to finish off the engine wiring loom and fuel system. I bought 2x Innovate LC-2 Wideband Lambda sensor kits which uses the Bosch LSU 4.9 sensors. This kit came with it's own wiring connectors, so I had to open up the loom again to remove the original wiring and add the new cables in.

I also changed the route of some of the wires to make a T shape behind the engine rather than a +.

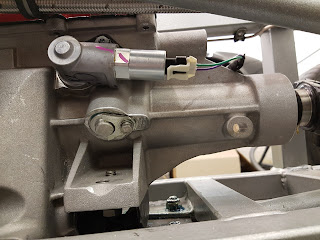

I made some stainless steel brackets to hold the Bosch sensor connectors. These were cut from 2.5mm stainless plate and a square hole was made and the connectors are an interference fit to prevent the connectors from falling out. These were bolted to the engine block with M6 set screws.

I received the proper connectors for the knock sensors. These were ACDelco PT #2652 to go with the LS Gen IV Sensors (GM #12570125). I cut off the old ones from the loom to shorten the cables to neaten the installation.

The fuel hose fittings just need to be tightened to finalize, but overall I think it looks like a neat job and I am happy with it. For now............

I also changed the route of some of the wires to make a T shape behind the engine rather than a +.

I made some stainless steel brackets to hold the Bosch sensor connectors. These were cut from 2.5mm stainless plate and a square hole was made and the connectors are an interference fit to prevent the connectors from falling out. These were bolted to the engine block with M6 set screws.

I received the proper connectors for the knock sensors. These were ACDelco PT #2652 to go with the LS Gen IV Sensors (GM #12570125). I cut off the old ones from the loom to shorten the cables to neaten the installation.

The fuel hose fittings just need to be tightened to finalize, but overall I think it looks like a neat job and I am happy with it. For now............

Wednesday, 15 February 2017

Fuel System - Continued

I made a bracket to hold the fuel pressure regulator out of 2.5mm thick stainless. I left a side cut out in it to aid removal of the wiring loom where it passes through the bulkhead. I then finished off the fuel hose fittings to ensure they fitted correctly from each fuel rail.

I then drilled a larger hole in the air inlet to fit the Inlet Air Temperature sensor. A 16mm grommet was used.

Monday, 16 January 2017

Engine Wiring Harness

Since all the sensors have been installed, I thought I had better install the extra wires required for the harness so that the sensors could be utilised. I laid the harness onto the engine and opened up the flexible conduit wrapping to add in the extra cores.

The wire was bought from SimtekUK, and are 1.00 sqmm in area.

I used a mixture of black insulating tape and some fibre tape to close the conduit up again. I ran the following additional wires:

2x wires for the Oil Temperature Sensor

2x wires for the Oil Pressure Sensor

2x wires for the Coolant Temperature

2x wires for the Reverse Lockout Solenoid

4x wires for the Wideband Lambda Sensors (2x per side)

3x wires for the Oil Sump level Switch (May connect in the future)

I tried to work out how best to run the extra wires, and I decided to run them alongside the wires that go to the ECU connector. These will be fitted with connectors once the dashboard is fitted when I work out where everything needs to go.

The wire was bought from SimtekUK, and are 1.00 sqmm in area.

I used a mixture of black insulating tape and some fibre tape to close the conduit up again. I ran the following additional wires:

2x wires for the Oil Temperature Sensor

2x wires for the Oil Pressure Sensor

2x wires for the Coolant Temperature

2x wires for the Reverse Lockout Solenoid

4x wires for the Wideband Lambda Sensors (2x per side)

3x wires for the Oil Sump level Switch (May connect in the future)

I tried to work out how best to run the extra wires, and I decided to run them alongside the wires that go to the ECU connector. These will be fitted with connectors once the dashboard is fitted when I work out where everything needs to go.

I also dressed the engine harness using some stainless P-Clips and some short M10 Cap Head Set Screws.

I mounted the knock sensors to each side of the block. I used GM #12623730 sensors which are for the MK IV LS Engines. I realise now that I need the correct mating plug for them. I will change them when it they arrive. The mating plug part number is GM #13580877.

Once the starter was connected up, and the crank sensor plugged in, I fixed in the heatshield using one of the bellhousing bolts and an M10 Set Screw.

I crimped on the connectors for the following sensors:

Reverse Light Switch - Part Number Delphi 12015792

Vehicle Speed Sensor - Part Number Dorman 645-213

Reverse Lockout Solenoid - Part Number Delphi 12052646

3-Pin Sensors - Part Number GM #12551708 (CON-323 from SimtekUK)

Altogether quite neat I think. Just neat to finalise the harness onto the fuel rails:

Tuesday, 8 November 2016

Sensored!

I decided to over complicate my Oil Pressure & Oil / Water Temperature sensors for the gauges. I thought it would be a good idea to have the possibility of having the measurements input to a data logger of some kind. I opted to buy sensors from GM that have dual circuitry.

They have 3 pins. One pin is for the gauge, and the other two pins are for a 5V signal into an ECU / Data Logger. I thought that this would future proof my install in case I wanted to add the data logging function.

After surfing the net for a while, I discovered that the correct part numbers were:

Oil / Water Temperature Sensor (3-Wire): GM# 12551708

Oil Pressure (3-Wire): GM# 12616646

These have the correct threads / sealing washer to be able to screw straight into the LS engine without any adapters.

I found out (I haven't verified this myself) that these sensors are of US 280F range, so I'm assuming a gauge won't be an issue.........

Also, I bought the 3-pin connectors from Simtek UK (CON-323): Direct Link

I need to put some extra wiring into the loom to accommodate the sensors, and I will post when that is done.

I had to drill and tap the housing above the oil filter since this was blanked off. This was done by removing it from the engine, drilling and tapping it to M12 x 1.5mm (Not a standard M12 thread). This was fully cleaned from debris before bolting back together.

I hope they work.......

They have 3 pins. One pin is for the gauge, and the other two pins are for a 5V signal into an ECU / Data Logger. I thought that this would future proof my install in case I wanted to add the data logging function.

After surfing the net for a while, I discovered that the correct part numbers were:

Oil / Water Temperature Sensor (3-Wire): GM# 12551708

Oil Pressure (3-Wire): GM# 12616646

These have the correct threads / sealing washer to be able to screw straight into the LS engine without any adapters.

I found out (I haven't verified this myself) that these sensors are of US 280F range, so I'm assuming a gauge won't be an issue.........

Also, I bought the 3-pin connectors from Simtek UK (CON-323): Direct Link

I need to put some extra wiring into the loom to accommodate the sensors, and I will post when that is done.

I had to drill and tap the housing above the oil filter since this was blanked off. This was done by removing it from the engine, drilling and tapping it to M12 x 1.5mm (Not a standard M12 thread). This was fully cleaned from debris before bolting back together.

I hope they work.......

Subscribe to:

Posts (Atom)